Comprehensive Lead Paint Removal Service in NYC-- Accredited and Qualified

Comprehensive Lead Paint Removal Service in NYC-- Accredited and Qualified

Blog Article

Important Devices and Strategies for Effective Lead Offense Cleaning

Dealing with lead violations properly requires a thorough method that mixes the right devices with tactical techniques. Concurrently, the use of specialized cleanup devices, such as HEPA vacuum cleaners and lead-specific cleaning agents, is important for detailed contaminant elimination. Reliable containment techniques, consisting of plastic sheeting and unfavorable air stress systems, are essential to avoid the spread of unsafe products.

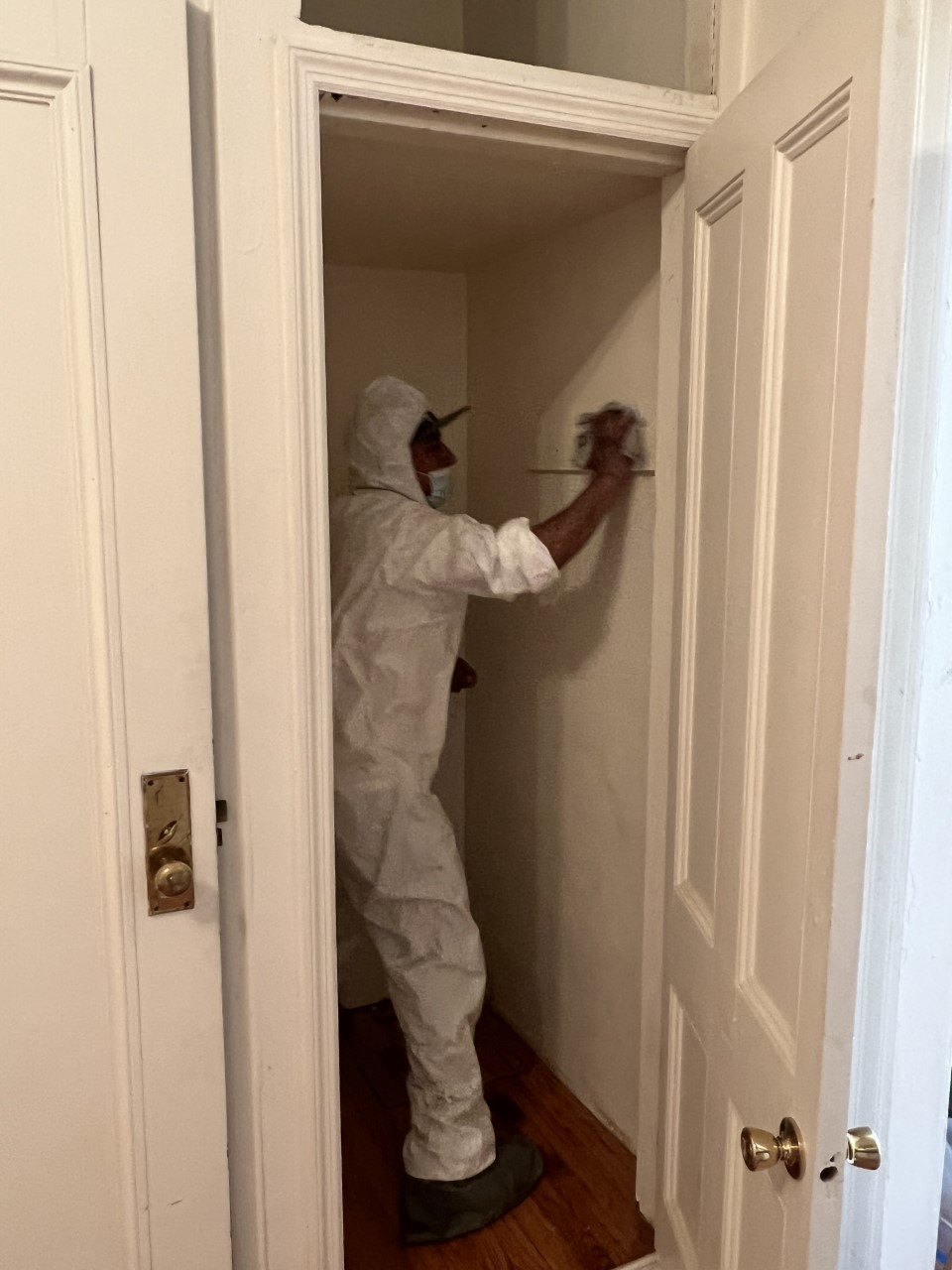

Personal Protective Tools

Personal protective devices (PPE) is an essential part in the reliable monitoring of lead contamination cleaning. The essential PPE for lead cleanup consists of respirators, safety apparel, handwear covers, and eye security.

Respirators, especially those geared up with HEPA filters, are essential for filtering air-borne lead bits, preventing breathing. Protective apparel, consisting of coveralls and disposable matches, stops lead dust from sticking to employees' garments, minimizing the danger of secondary contamination.

Additionally, rigorous training on the right use and maintenance of PPE is vital. Workers have to be enlightened on putting on and doffing treatments to prevent contamination. Regular assessments and replacements of PPE parts are required to keep their protective capacities, guaranteeing a risk-free and compliant clean-up procedure.

Specialized Cleanup Equipment

One more essential tool is the wet/dry vacuum cleaner, which can effectively tidy up both dust and liquid impurities. These vacuums commonly come with HEPA filters to supply an additional layer of security. Damp cleans or tack fabrics are additionally crucial for surface cleansing; they are specifically created to record and hold lead particles, minimizing the threat of spreading contamination.

For even more stubborn deposits, specialized lead-removal cleansing representatives are required. These agents are created to damage down lead particles, making them less complicated to remove. Scrub brushes with durable bristles can help in this procedure, specifically on rough surfaces where lead dirt often tends to stick more strongly.

Additionally, encapsulants are utilized to secure lead-contaminated surface areas, protecting against the launch of lead dust. These specialized paints and finishings are created to abide by different substrates, providing a long-term solution for lead control.

Efficient Containment Techniques

Efficient containment methods are crucial in minimizing the spread of lead contamination during clean-up tasks. Implementing robust containment techniques makes sure that lead bits do not migrate to unaffected locations, therefore securing both workers and the environment. One primary approach is using plastic sheet to seal contaminated areas. Durable polyethylene barriers can be installed from flooring to ceiling to produce a controlled workspace, substantially minimizing the danger of airborne lead dirt dispersal.

To improve containment, encapsulants can be put on surface areas that are not being removed or interrupted. These specialized coatings bind lead dirt, lowering its availability for resuspension. In addition, all employees have to use proper Personal Safety Equipment (PPE), consisting of respirators and disposable matches, to stop contamination spread.

Safe Disposal Practices

Making sure safe disposal techniques is an important component in the monitoring of lead contamination cleanup. Correct disposal reduces the threat of lead returning to the environment and endangering public wellness. The very first step is to identify and go to website set apart lead-contaminated waste from various other materials. Secure control utilizing heavy-duty, watertight containers is necessary to avoid splilling throughout transportation.

Transferring lead waste needs adherence to rigorous standards. Using certified harmful waste service providers guarantees that the products are taken care of responsibly. Paperwork, consisting of manifests describing the kind and quantity of waste, ought to come with shipments to track the waste from the website of origin to its final disposal location.

Designated contaminated materials disposal centers are geared up to take care of lead-contaminated products securely. These facilities usually employ innovative approaches such as stabilization, solidification, or chemical therapy to neutralize the lead before disposal. Landfilling in specialized, lined areas that protect against leachate from polluting groundwater is an usual method for final disposal.

Regular training for employees associated with lead garbage disposal is see critical to preserve security standards and prevent unintentional exposure. By sticking to these techniques, companies can dramatically lower the environmental and health and wellness impacts associated with lead contamination.

Regulatory Compliance Tips

Sticking to governing conformity is vital in the effective execution of lead contamination cleanup. Understanding and adhering to federal, state, and neighborhood guidelines makes certain not just the safety and security and health and wellness of individuals but also the lawful and financial health of the clean-up organization. The Epa (EPA) sets rigid standards, such as the Lead Improvement, Repair Service, and Painting (RRP) Policy, which mandates proper accreditation and training for contractors taking care of lead-based activities.

Compliance begins with a thorough evaluation of relevant laws and policies. Organizations has to stay updated on any kind of legislative modifications, which can be promoted through normal training sessions and subscribing to sector updates. Documentation is an additional crucial conformity facet; preserving thorough documents of all tasks, including evaluation records, worker training logs, and disposal shows up, is essential.

Furthermore, involving with accredited lead assessors or take the chance of assessors ensures that lead risks are properly determined and reduced. Employers need to apply making use of Personal Protective Equipment (PPE) and guarantee that security procedures are purely adhered to. Clear communication with stakeholders, including employees, clients, and regulatory bodies, will certainly promote a culture of compliance and accountability, eventually contributing to a safer and much more effective lead cleanup procedure.

Verdict

Efficient lead infraction cleaning necessitates the combination of specialized devices and look at this now tactical methods to ensure security and efficacy. Personal safety equipment (PPE) safeguards employees from direct exposure, while safe disposal techniques and strict adherence to governing compliance are crucial for properly taking care of dangerous waste.

Report this page